The company has been operating on the CNC machining market since 2008. Thanks to our experience and acquired knowledge, we can offer both high-level products and an unconventional approach to every order. We carry out both production of single components and whole series of subassemblies, always maintaining the highest quality of workmanship.

We have been operating in the precision metalworking industry since 2008. During this time we have gained a lot of experience, which, combined with modern machinery and extremely precise machining centers, allows us to take on the most complex orders from our customers.

We are a very ambitious and close-knit team, and thanks to good communication, responsibility and mutual support, we undertake increasingly complex and complicated projects. This is made possible by our modern machinery consisting of 3-, 4- and 5-axis milling machines, supplemented by lathes and EDM machines, operating with CNC technology.

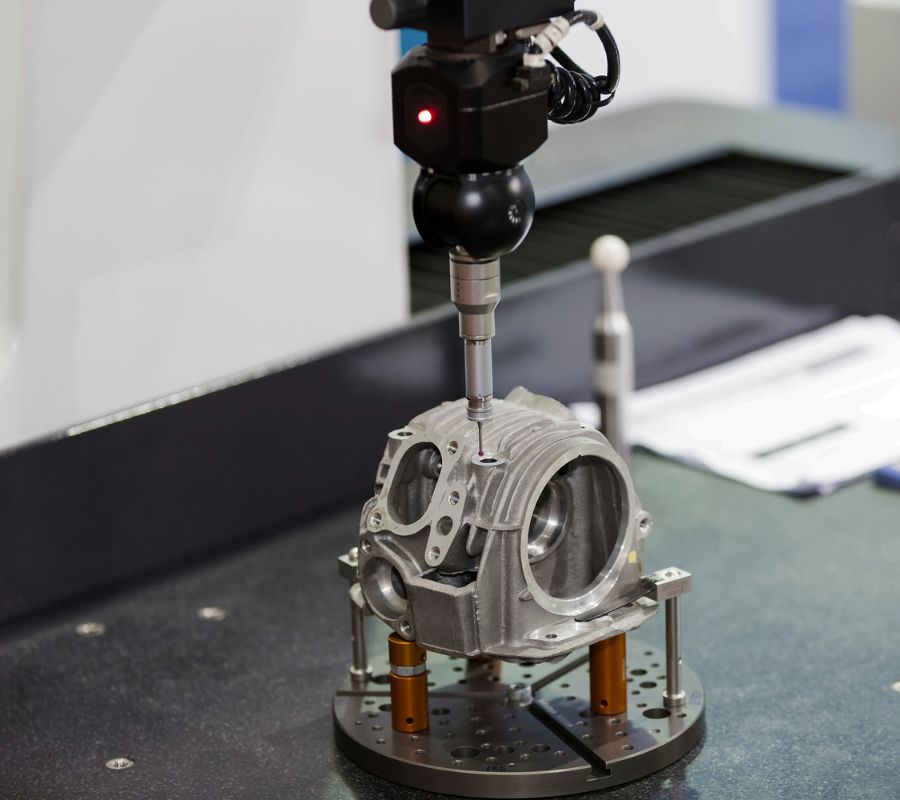

We undertake both large and small orders, always maintaining high quality workmanship. We have our own design and technology office and a professional measurement laboratory, so we prepare technical documentation ourselves and offer assistance in designing machine elements.

We work using our own materials or those supplied by the client. Each order is priced individually on the basis of the delivered project.

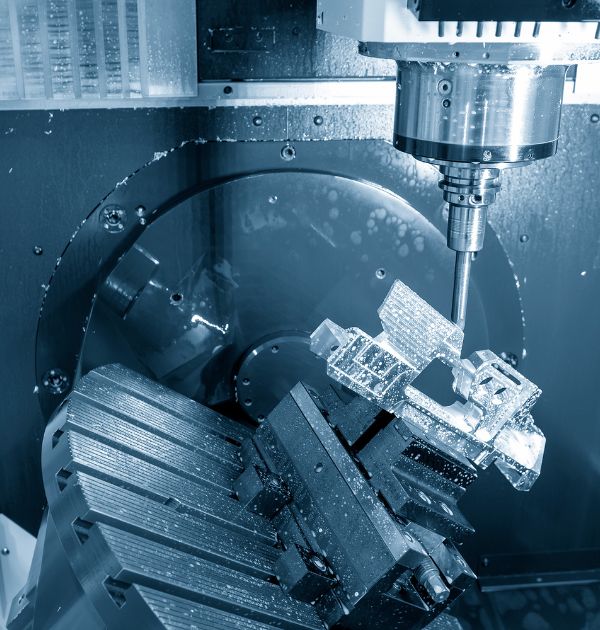

Milling using a multi-edged tool called a cutter on a numerically controlled machine, known as a CNC milling machine.

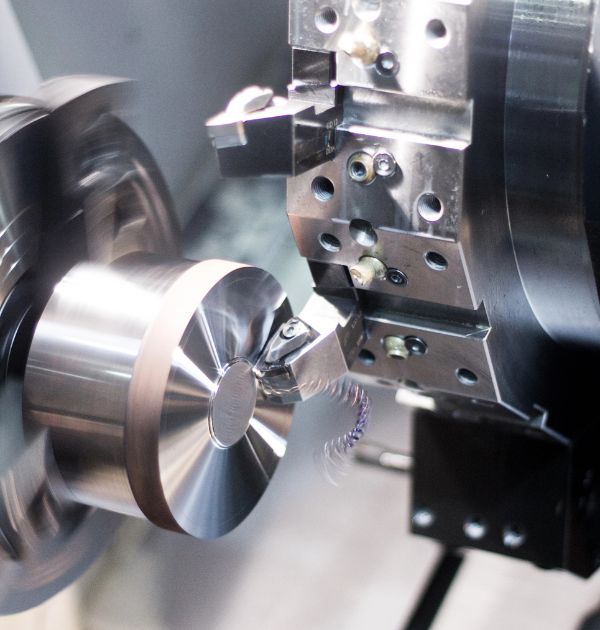

In turning, the workpiece rotates around its own axis, while the cutting tool moves relative to it, shaping the object according to the set parameters.

A wire EDM machine is mainly used for the production of dies, mold components, and tools.i.

urface grinding is one of the final steps in the production process of a given part, aimed at achieving very precise shape and dimensional accuracy.

We specialize in the production of spare parts to maintain operations for several large manufacturing companies in and around Poznań.